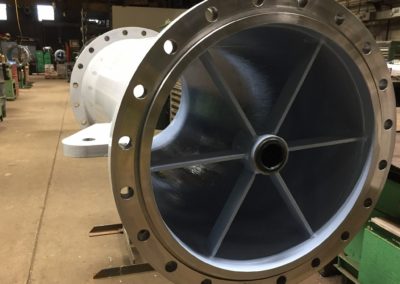

Municipal Maintenance Company specializes in the repair of all types of pumps, all manufacturers, and sizes. Whether it be a simple bearing change-out or a difficult failure analysis, MMC is equipped to handle it. Our full service machine shop allows us to keep your costs down. If a housing or shaft is damaged, repairs will be considered before the costly route of replacement. This allows MMC to provide added value and decreased downtimes. As with all repair services, Municipal Maintenance Company offers turnkey service including; removal, repair, installation, laser alignment (if needed), and start-up testing.

The process of a pump repair typically begins with a pressurized steam cleaning, followed by the disassembly of the pump to allow for a detailed inspection of all parts. In addition to finding the cause of a failure, all factory specifications will be confirmed. This includes housings, journals, and wear-clearances. All parts are then sandblasted, cleaned, and primed. The machine shop and fabrication shop will then complete any necessary repairs before the pump enters the assembly stage. At this time all pump impellers are dynamically balanced on a state-of-the-art Schenck Trebel balancing machine. Assembly is then performed by the same mechanic that disassembled the pump. All mechanical seals are vacuum tested. The pump is then painted and tagged with a stainless steel ID tag used to reference the repair in the future. As a service to customers, MMC keeps all records of the repairs in their service history system.

MMC specializes in the repair of the following types of pumps: